المنتجات الساخنة

Rings Magotteaux

网页Rings are mostly used for coal grinding vertical ball mills (VBM), also known as pulverizers. As the rings are not segmented, they are supplied as monobloc castings and are

Contact

Full gear unit range for your horizontal mill

网页Our gear units work efficiently and reliably with the various types of horizontal mills in the cement and mining industries. We provide both central and lateral drive systems that use multistage spur gears,

Contact

Energy-Efficient Technologies in Cement Grinding

网页2016年10月5日F.L.Smidth has developed this cement grinding system which is a fully air-swept ring roller mill with internal conveying and grit separation. This mill is a major improvement of the cement grinding

Contact

polab® APM- Sample preparation for cement

网页Combined mill and press in one small unit with a minimum footprint of only 600 x 1230 x 735 mm (23.6 x 48.4 x 28.9 ″; W x H x D) Patented grinding unit for efficient and gentle grinding, and optimized sample preparation

Contact

Cement grinding optimisation ScienceDirect

网页2004年11月1日The increasing demand for “finer cement” products, and the need for reduction in energy consumption and green house gas emissions, reinforces the need for

Contact

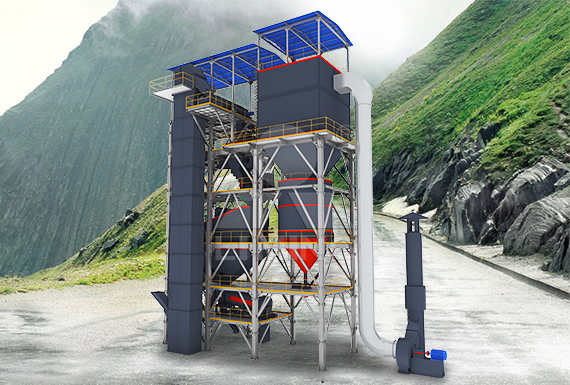

Cement Grinding Unit Cement Grinding Plant

网页Process of cement grinding station. The process of cement grinding station can be divided into three types: open-circuit grinding system, closed-circuit grinding system, and combined grinding system. Open

Contact

important operation tips for cement vertical mill

网页In the vertical grinding operation process, to form a stable material layer, it is required that the grinding material has a suitable gradation, and more than 95% of the particle size is less than 3% of the roller diameter.

Contact

Flexible milling and grinding solutions that last

网页With years of experience in the cement and mining industries and over 3000 mills sold worldwide, continues to develop its range of efficient milling and grinding solutions. This experience and know-how, as well

Contact

Vertical Roller Mills

网页Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition monitoring services enable you to adopt a proactive maintenance

Contact

Grinding aids for high performance cements C-ADD Mapei

网页Cement Additives Division 1 Grinding aids for high performance cements M.Magistri, P.Recchi, Mapei SpA, Milan, Italy Introduction The interest in high performance cements has been growing in the last years, as a natural consequences of high performance concrete production. Cement producers are requested to offer

Contact

Cement industry solutions ABB

网页Global cement producer Votorantim Cimentos achieves multi-site digitalization with ABB industry-specific solutions. 2022-04-05. ABB upgrades process control systems and cement grinding units in UAE

Contact

Full gear unit range for your horizontal mill

网页Our gear units work efficiently and reliably with the various types of horizontal mills in the cement and mining industries. We provide both central and lateral drive systems that use multistage spur gears,

Contact

polab® APM- Sample preparation for cement

网页polab® APM advantages at a glance. Combined mill and press in one small unit with a minimum footprint of only 600 x 1230 x 735 mm (23.6 x 48.4 x 28.9 ″; W x H x D) Patented grinding unit for efficient and gentle

Contact

(PDF) Performance Evaluation of Vertical Roller Mill

网页2017年9月11日For grinding cement, two types of mills are used ball and roller. Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials.

Contact

Effect of Polycarboxylic Grinding Aid on Cement

网页2022年9月19日The average particle diameter of cement was reduced by 3.65 μm when 0.03 wt% of PC was added as grinding aid. Moreover, high initial fluidity of the cement paste, 290 mm, could be reached when 0.08

Contact

Optimizing cement grinding with chemical additives

网页2019年4月23日Cement additives are chemicals that are used to improve cement grindability and/or performance. This is accomplished by addressing several challenges in the production of cement. For example, as cement

Contact

Cement grinding: VRM or ball mill?

网页2019年2月9日Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing process. However, despite the fact that more than 10 years has passed since the

Contact

Flexible milling and grinding solutions that last

网页With years of experience in the cement and mining industries and over 3000 mills sold worldwide, continues to develop its range of efficient milling and grinding solutions. This experience and know-how, as well

Contact

Vertical Roller Mills

网页Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

Contact

Grinding aids for high performance cements C-ADD Mapei

网页Cement Additives Division 1 Grinding aids for high performance cements M.Magistri, P.Recchi, Mapei SpA, Milan, Italy Introduction The interest in high performance cements has been growing in the last years, as a natural consequences of high performance concrete production. Cement producers are requested to offer

Contact

Cement industry solutions ABB

网页Global cement producer Votorantim Cimentos achieves multi-site digitalization with ABB industry-specific solutions. 2022-04-05. ABB upgrades process control systems and cement grinding units in UAE

Contact

(PDF) Performance Evaluation of Vertical Roller Mill

网页2017年9月11日For grinding cement, two types of mills are used ball and roller. Recent decades have proven the great effectiveness of a vertical roller mill for grinding raw materials.

Contact

Effect of Polycarboxylic Grinding Aid on Cement

网页2022年9月19日The average particle diameter of cement was reduced by 3.65 μm when 0.03 wt% of PC was added as grinding aid. Moreover, high initial fluidity of the cement paste, 290 mm, could be reached when 0.08

Contact

Optimizing cement grinding with chemical additives

网页2019年4月23日Cement additives are chemicals that are used to improve cement grindability and/or performance. This is accomplished by addressing several challenges in the production of cement. For example, as cement

Contact

Cement grinding plant Xinxiang Great Wall Machinery Co., Ltd

网页The Performance Characteristics of Cement Grinding Station: The cement grinding station uses precrushing technology, so that it reduces the granularity of the materials that are fed into the grinding Riding ring of rotary kiln. 4 Pages. Grinding table for vertical mill. 4 Pages. Grinding roller for vertical mill. 4 Pages. features. 5

Contact

important operation tips for cement vertical mill

网页The material layer is too thick will lead to grinding efficiency reduction, and when pressure difference of the mill reaches the limit, the material will collapse, which will affect main motor and venting system; If material

Contact

Cement Grinding Cement Plant Optimization

网页Water Spray in Cement Mills. Water spray installed generally in second compartment of ball mill to control cement temperature. Cement discharge temperature should be kept below about 110 o C but, the same time should allow some 60% dehydration of gypsum to optimize cement strength without excessive false set.

Contact