المنتجات الساخنة

On-line measurement of pulverized coal fineness on a 300

网页2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coal-fired power plants, demanding accurate and on-line monitoring. This study presents on-line

Contact

Online monitoring of coal particle size and flow

网页2016年4月5日 Pulverized coal fineness (PCF) is a key parameter in coal-fired power plants, demanding accurate and on-line monitoring. This study presents on-line

Contact

On-line measurement of pulverized coal fineness on a 300

网页2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coal-fired power plants, demanding accurate and on-line monitoring. This study presents on-line

Contact

On-line measurement of pulverized coal fineness on a 300

网页2021年3月1日 This study presents on-line measurement of PCF on a 300 MWe coal-fired power plant with pulsed digital inline holography (DIH). A prototypal instrumentation

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年11月15日 A method for choosing the optimum fineness of coal in pulverised-fuel boilers is presented. This method is based on economic criteria and takes into account

Contact

CPRI Online Coal Flow Balancing and Fineness

网页2020年3月19日 ABSTRACT:The stone describes the beneficial application of online coal flow measurement and control and online coal fineness measurement for optimization of

Contact

Pulverizer Fineness

网页Mesh is achieved. When >10% fuel imbalance is observed, burner lines with higher fuel flows typically have less desirable fineness. Burner lines that have less fuel typically have better coal fineness. When this occurs the

Contact

Improved Coal Fineness Improves Performance, Reduces

网页2011年10月1日 Coal fineness is a relative measurement of particle size distribution typically applied to the product leaving a pulverizer. Standardized wire mesh screens are

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年8月1日 Pulverized coal fineness (PCF) is a key parameter in coal-fired power plants, demanding accurate and on-line monitoring.

Contact

CN104374675A Coal mill pulverized coal fineness online

网页The invention discloses a coal mill pulverized coal fineness online monitoring method; according to a pre-established model, during running, the coal mill dynamic separator

Contact

On-line measurement of pulverized coal fineness on a 300

网页2021年6月1日 Particle size distribution (PSD) of coal powder, so-called pulverized coal fineness (PCF) [2 ], is a crucial parameter in coal-fired power plants, with a significant effect on combustion efficiency [ 3 ], wear of equipment, and emissions [ 4, 5 ].

Contact

On-line measurement of pulverized coal fineness on a 300

网页2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coal-fired power plants, demanding accurate and on-line monitoring. This study presents on-line measurement of PCF on a 300 MWe coal-fired power plant with pulsed digital inline holography (DIH).

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年11月15日 By the term “quality of pulverized coal” is understood its fineness (cumulative percentage retained R0.09 and R0.20) in conjunction with its homogeneity described by the uniformity (polydispersity) number n.

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年11月15日 The major aim of this optimisation is creating an effective tool for determining the value of R 0.09 that is the best at a given time from the economical point of view. The optimum value of R 0.09 corresponds with the minimum value of the total cost defined further in eq. (1).Using the algorithm can give savings for a power plant without

Contact

ECT: more than just coal-flow monitoring Modern Power

网页2002年3月5日 Thus, the ECT system can be used to monitor mill performance on-line assuring proper coal fineness is maintained to minimise unburned carbon. The ECT system consists of receiving antennas in each coal conduit that are connected to a signal conditioning unit. The signal conditioning unit is in turn connected to a PC for data

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年8月1日 Particle size distribution (PSD) of coal powder, so-called pulverized coal fineness (PCF) [2], is a crucial parameter in coal-fired power plants, with a significant effect on combustion...

Contact

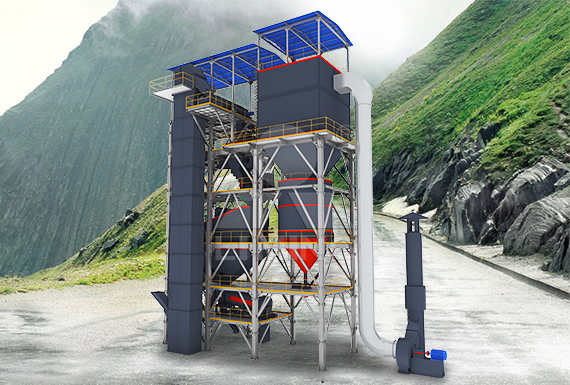

Power Pulverizers

网页2023年6月7日 To efficiently combust coal, it needs to be pulverized into fine particles (100μm) before being placed in a boiler. A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal

Contact

Reliable Coal Pulverizers and Mills ? BabcockWilcox

网页Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Contact

CFD based investigations into optimization of coal

网页2009年9月1日 A dimensional sketch of a typical pulverizer is presented in Fig. 1 (a).A schematic diagram showing the air and particle streams in a pulverizer are presented in Fig. 1 (b). The raw coal from the coal feed chute (8) mixes with returned oversize material (7) to form a mixed stream that passes between the grinding balls and bottom grinding ring in

Contact

online coal pulveriser fineness

网页online coal pulveriser fineness. 2021-08-05T11:08:33+00:00. Pulverizer Wikipedia. With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to 995% or higher . 50 mesh and 80% or higher ; 200 mesh, while one equipped with a dynamic classifier produces coal fineness levels . Full

Contact

On-line measurement of pulverized coal fineness on a 300

网页2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coal-fired power plants, demanding accurate and on-line monitoring. This study presents on-line measurement of PCF on a 300 MWe coal-fired power plant with pulsed digital inline holography (DIH).

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年11月15日 The major aim of this optimisation is creating an effective tool for determining the value of R 0.09 that is the best at a given time from the economical point of view. The optimum value of R 0.09 corresponds with the minimum value of the total cost defined further in eq. (1).Using the algorithm can give savings for a power plant without

Contact

Optimisation of coal fineness in pulverised-fuel boilers

网页2017年8月1日 Particle size distribution (PSD) of coal powder, so-called pulverized coal fineness (PCF) [2], is a crucial parameter in coal-fired power plants, with a significant effect on combustion...

Contact

Boiler Mill and Coal Pulverizer Performance GE Steam

网页2023年6月6日 YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions. This is the Power of Yes.

Contact

Reliable Coal Pulverizers and Mills ? BabcockWilcox

网页Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Contact

CFD based investigations into optimization of coal

网页2009年9月1日 A dimensional sketch of a typical pulverizer is presented in Fig. 1 (a).A schematic diagram showing the air and particle streams in a pulverizer are presented in Fig. 1 (b). The raw coal from the coal feed chute (8) mixes with returned oversize material (7) to form a mixed stream that passes between the grinding balls and bottom grinding ring in

Contact

Experimental study effect of classifier pulverizer opening

网页2019年12月10日 Download Citation Experimental study effect of classifier pulverizer opening setting variation on fineness production passed 200 mesh In coal-fired power plants, the performance of the

Contact

Dynamic classifiers improve pulverizer

网页2007年7月15日 The fineness of coal is measured using a U.S. standard sieve with a sleeve opening of 0.0030 inches. Particles smaller than 74 microns will pass through a 200-mesh screen, and those larger will not.

Contact

Pulveriser PDF Wear Chemical Engineering Scribd

网页2019年3月23日 of 17 PULVERISERFAN PERFORMANCE BY SRI SANJIB BERA PULVERISER Pulverisers are selected to provide a required grinding capacity, based upon a set of design criteria that include the required coal particle fineness and coal characteristics. The required pulveriser capacity is determined by the boiler heat input

Contact

online coal pulveriser fineness

网页online coal pulveriser fineness. 2021-08-05T11:08:33+00:00. Pulverizer Wikipedia. With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to 995% or higher . 50 mesh and 80% or higher ; 200 mesh, while one equipped with a dynamic classifier produces coal fineness levels . Full

Contact